Is the North Country fertile ground for the next Silicon Valley? Visionaries see potential, with PSU playing the pivotal role of academic hub. Dreams of the future are supported by today’s high-tech realities, including the University’s new robotics and applied mathematics disciplines, and a new, state-of-the-industry facility comparable to those of the nation’s top technology institutions.

Plymouth State’s new “maker-space” in the Draper & Maynard building boasts state-of-the-industry equipment that has students dreaming big: self-driving snowmobiles, a “mesh network” (or meshnet) to boost and extend Wi-Fi sensors, electronic car motors, and large mammal prosthetics are among the early ideas. Faculty, staff, and students of all disciplines are welcomed to the facility after attending general safety workshops and specific sessions on 3D printing and laser cutting. The makerspace is a regional resource, and plans call for public access, including opening it to local industries over the next year.

“We’ve brought to bear a wide variety of equipment, and there really isn’t anything else like this. It’s a unique and broad facility comparable to those of leading institutions such as Harvard and MIT.”

—Bret Kulakovich, PSU’s Coordinator for Academic Spaces and Open Lab Design

The facility’s capabilities represent a paradigm shift in manufacturing, according to Bret Kulakovich, PSU’s coordinator for academic spaces and open lab design. Kulakovich designed the makerspace and has led the University’s conceptualization through work with campus constituencies. “Methods for supplying consumer goods are on the cusp of great change, as more and more fabricating can now take place closer to the end user,” he says. “Our new makerspace brings these exciting capabilities to PSU.”

Kulakovich illustrates his point by using a common household item as an example. When a Tupperware top needs replacing, under the current system, thousands and thousands of replacements must be produced at factory scale, and ships, planes, railcars, and tractor-trailers then make deliveries of finished goods worldwide in a logistical symphony.

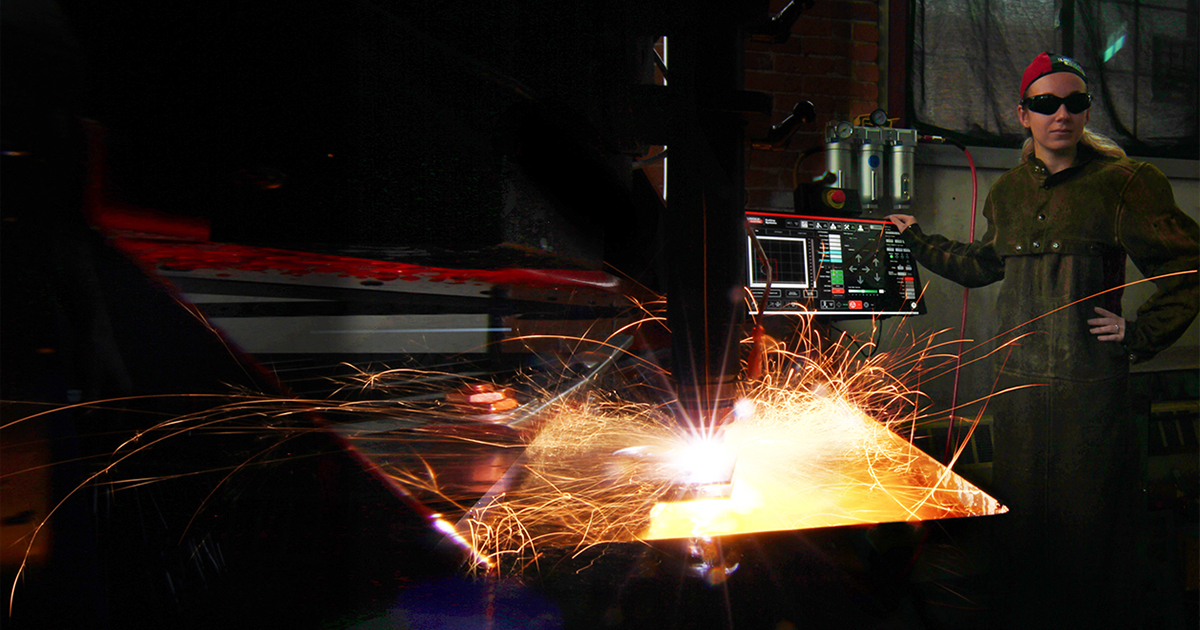

An alternative manufacturing strategy would be to produce a single top at a location nearby, or perhaps even in the end user’s home. Such is the premise of a plasma table, one of several high-tech makerspace machines.

“We’ve got a manufacturing-based culture that’s over 100 years old, where we mass produce things,” says Kulakovich. “The production line did a huge amount for absolutely everyone, knocking out cars and insulin and other drugs, but we’re getting to the point where that strategy doesn’t work so well anymore. We make lots of products that people never buy and that wind up in landfills.”

The plasma table is part of an impressive equipment array that is giving students many new opportunities. Between substantial, essential renovation of the historic Draper & Maynard Building’s first floor and purchase of new equipment, the makerspace represents a $1 million upgrade. As PSU’s newest Open Laboratory, it’s a place for learning, experimenting, and collaborating with other majors, businesses and nonprofits, and other community partners. The facility provides an extraordinary opportunity for students to work in cutting-edge technology across the entire spectrum of additive manufacturing and design.

The space accounts for over 2,000 square feet on D&M’s first floor, including an area devoted to PSU’s new Electromechanical Technology and Robotics (EMTR) discipline. Plans call for dedicated classrooms, computer labs, and additional fabrication space on D&M’s fourth floor.

“We’ve brought to bear a wide variety of equipment, and there really isn’t anything else like this,” says Kulakovich. “It’s a unique and broad facility comparable to those of leading institutions such as Harvard and MIT.”

Jess Sullivan ’20 is the makerspace’s student fellow. The interdisciplinary studies major has many PSU activities to his credit, including founding the University’s Creation Technology & Hacking Club and printing 3D topographic reliefs for the geography department, which he presented with other members of the PSU community at the American Association of Geographers 2019 annual meeting.

Sullivan sees the phenomenon of a makerspace as a brick-and-mortar extension of the now very refined Open Source Software (OSS) world, in which individuals can modify and share publicly accessible resources. “The potential value of the D&M makerspace as a scholarly and financial asset to Plymouth State is both large and sensitive enough that my Senior Seminar focus is entirely on forming a proper white paper detailing means to its success,” says Sullivan.

Along with EMTR students, the makerspace will be busy with students from other Clusters working on a variety of projects, including physical computing, health care, theatrical automation, environmental sciences, and hydroponics, among many other areas of interest.

“The makerspace is really going to provide the technology to let our students expand the scope of what’s possible in our theatre productions,” says Bob Bruemmer, PSU’s interim manager of theatre operations. “The tools will allow us to generate scenery more quickly and accurately and add a level of complexity that we haven’t had before. For example, the ShopBot lets us accurately generate multiple pieces in a short amount of time, the iron worker will help us quickly build scenery pieces and curved railings, and 3D printers will be great for custom and specialized props. We are very excited about what the makerspace will allow us to do.”

From computer-controlled cutting of wood, plastic, and metal to laser-sharp detailing, 3D printing, and bending and shaping of steel plate and piping, the makerspace will endow PSU students with experience and knowledge that may lead to many high-tech career options.